Dow

Paving the way to a sustainable tomorrow

Robotics at #TeamDow: Enhancing safety and efficiency

At Dow, robotics is more than just a buzzword; it’s a fundamental part of our strategy to drive innovation and efficiency. We work together seamlessly to enhance productivity and improve the safety of our teams. From aerial to underground operations, drones and robots enable us to achieve new levels of safety, productivity and precision.

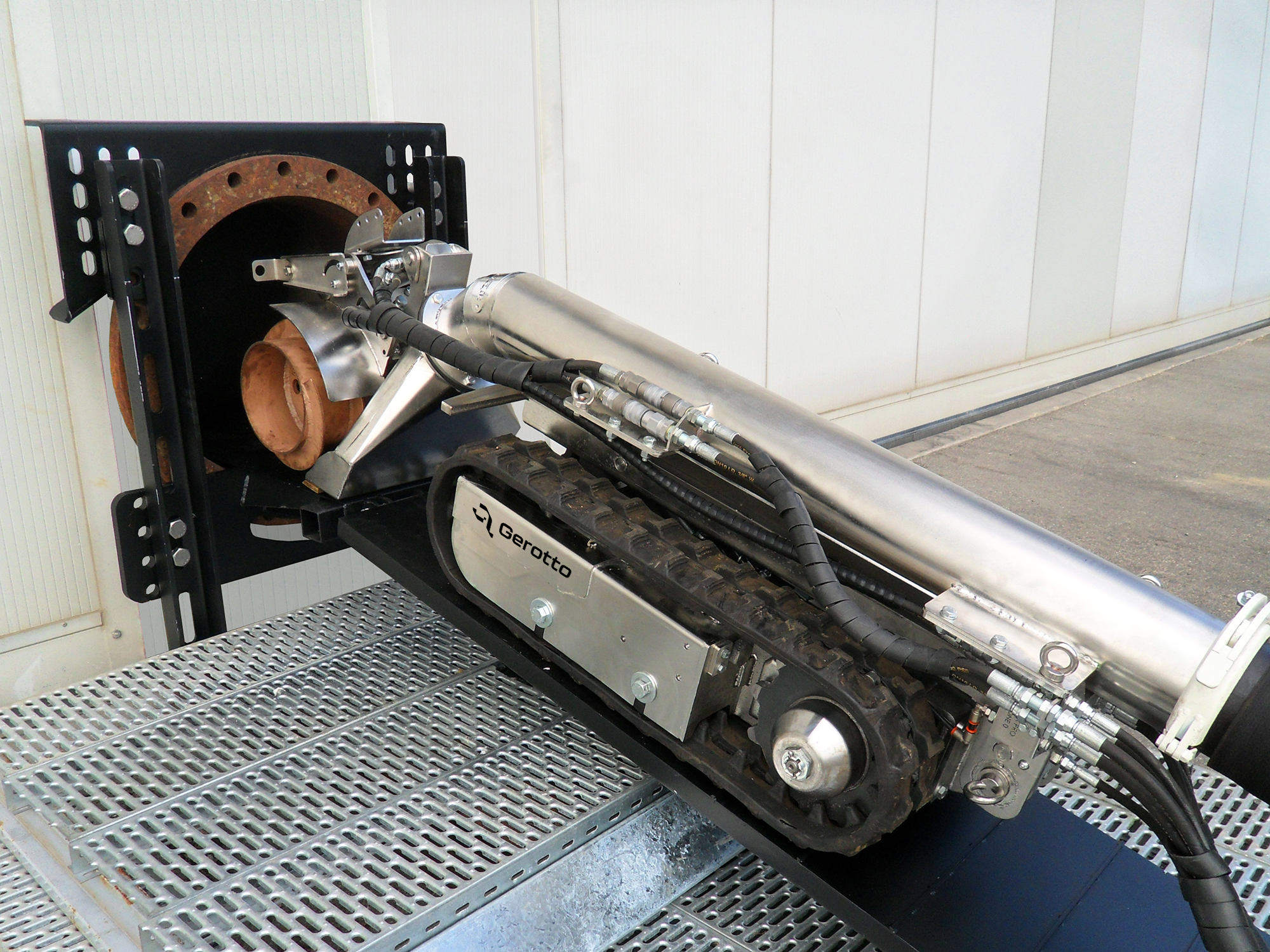

(AteX Zone 0 Robot - Courtesy of Gerotto. All rights reserved)

Let’s explore the fascinating world of technology and highlight a few exciting projects. Here’s how #TeamDow is making it happen.

Inside the vessel mission

An innovative solution was implemented to clean the vessel of compacted deposits without requiring personnel to enter the confined space. This is a great example of how we use robotics to enhance efficiency and safety. Dow utilized a remotely operated robot to effectively remove the deposits using Dow robotic technology to effectively extract the refined media from the vessel. Previously, this task would have involved multiple workers in full-body protective suits with supplied breathing air, taking several days to complete. With our robotic solution, we have done this job safely, much faster, and cost-effectively.

On the ground mission

A robotic platform adopted by #TeamDow was operated from another remote mobile control room that was equipped with specialized technology. This technology allows us to perform sub-surface tasks without risking damage to sensitive underground communications nearby. The entire job was carried out by the remotely operated robot, eliminating the need for personnel to be inside or in close proximity to the equipment. The complete job was done safely, efficiently, and cost-effectively!

Air mission

To ensure safe operation, our manufacturing equipment undergoes routine inspections. For large technological equipment, such as columns or reactors, inspection points are often located at high elevations. Typically, scaffolding must be erected to allow inspectors and their equipment access to these elevated areas. However, the construction of scaffolding carries risks associated with working at heights, is time-consuming, and can be quite costly.

Instead of the scaffold, #TeamDow utilized drone carrying equipment to perform the test. As a result, the entire inspection was completed in hours instead of taking several days. The work was done safely, efficiently, and with significant cost savings.

Do you want to stay up to day with Dow? Join our Join Our Talent Community | Jobs | Dow Corporate and we will send you email updates depending on what you'd like to learn more about.